Description

RIPSTOP BODYWARMER

- Resistant rip-stop product, with reinforced pockets.

- Comfort and freedom of movement with its elasticated armholes, side zips, fleece lined collar and inside drawstring.

- Intended to all market outlets and to workwear-focused campaigns.

Our product tracability

To trace our products through the production and distribution chain

A committed product

To guarantee you the best of our values

OEKO-TEX 4

STANDARD 100 by OEKO-TEX® stands for customer confidence and high product safety. STANDARD 100 label on a textile article means you can be certain that every component of this article, i.e. every thread, button and other accessories, has been tested for harmful substances and that the article therefore is harmless for human health. Independent institutes and laboratories that test the products take into account numerous regulated and non-regulated substances, which may be harmful to human health.

PETA

People for the Ethical Treatment of Animals (PETA) is the largest animal rights organization in the world, and PETA entities have more than 9 million members and supporters globally. PETA-Approved Vegan logo is highlighting clothing, accessories, furniture, and home decor items made of vegan alternatives to animal-derived materials, such as leather, fur, silk, feathers, and bone.

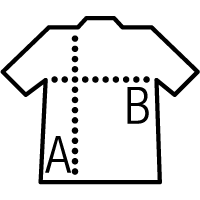

Which customisation technique for this product?

- Embroidery : This technique is generally used for personalisations that aim for a high-end finish. This technique is the most resistant to washing and use. The embroidery can be applied directly to the product or through embroidered patches. It can be done with thickness effects (with foam) or through patches that will then be affixed to the final product, allowing for variations in materials.

- Flex : It is the recommended marking technique for small and medium-sized series. There are several aspects: smooth, velvet, fluorescent, glitter, gold and silver. These are iron-on vinyls that are cut and glued by hot pressing. They are very well suited to a wide range of materials and substrates.

- Screen Printing : The most widely used technique. It consists, by the stencil method, of depositing the ink directly on the product. There are as many screens and passages as there are colours in the motif to be reproduced and all colours can be achieved. This technique makes it possible to produce very large quantities. It allows the use of inks with various effects for very different renderings and is adapted to almost all textile supports. The marking of coloured substrates requires an opacifying undercoat called « background white ».

- Transfert : The right technique for all materials. It is recommended for luggage, heavy garments, difficult to access surfaces. It consists of transferring the marking from a paper support to the garment by hot gluing. The marking by gluing brings rigidity to light supports at the level of the marking zone, nevertheless, the product keeps all its qualities of comfort.

Looks like you speak PLACEHOLDER,

would you like to visit this site in PLACEHOLDER?

Essential

Essential Windproof

Windproof Water Repellent

Water Repellent